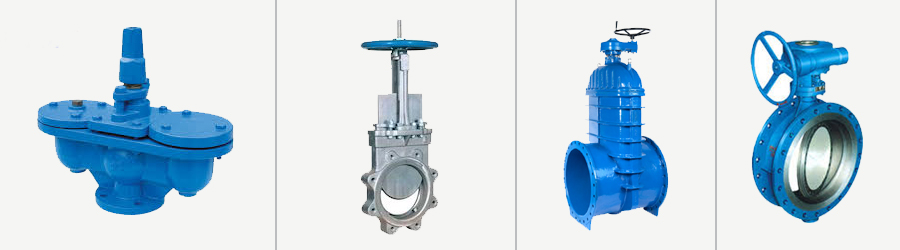

Globe Valve

A globe valve is much more acceptable of varied flow than the gate valve. It can operate barely open or fully open with very little wear to the valve seat and disc that is why recommended for throttling and balancing applications.

The flow can be gauged by the number of turns of the wheel. The contact between the seat and the disc ends when the flow begins, which minimizes seat erosion. Like the gate valve, the globe valve has a number of disc and seat arrangements. They are classified as conventional disc, plug-type disc, or composition disc. The conventional disc is a relatively flat disc with beveled edges. On closure of the valve, the disc is pushed down into a beveled, circular seat. The plug type disc is much more tapered, which increases the contact surface between the disc and the seat. "is type of disc is resistant to the cutting effects of the dirt, scale, and other foreign matter.

Unlike the other types of discs, the composition disc fits over the seat. This allows the valve to be used for many more services, such as compressed air, and makes it easy to repair.

The advantages of the globe valve are that it provides a positive bubble-tight shut off. It is good for frequent operation and it is easy to repair. Yet because of the flow path, it causes a significant pressure drop. Also, the globe valve is more costly than other types of valves.