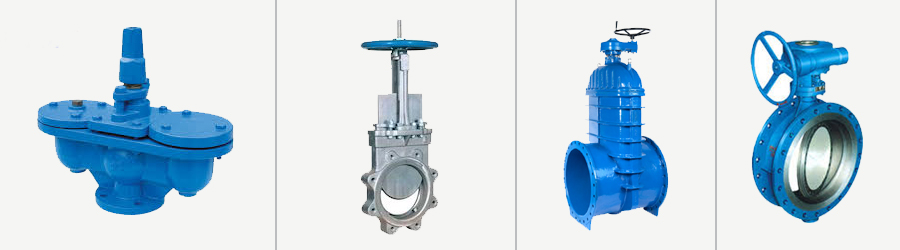

BUTTERFLY VALVES

A Butterfly valve consists of a cylindrical body, a shaft, and a rotating disc. The disc rotates 90 degrees from open to closed. The disc seats against a resilient body liner or spring-loaded metal seat and may be manufactured for tight shut-off or made smaller for reduced operating torque at lower close-off. Butterfly valves have limited range ability for modulating applications so are used mainly for two-way operation. For three-way applications, two butterfly valves are assembled to a pipe tee with linkage for simultaneous operation.

SHREE KRISHNA INDUSTRIES butterfly valves are well accepted in various water supply schemes all over India. Irrespective of sizes, pressure ratings, fluids handled, type of operators etc. The types of operators offered are Manual, Electrical, and Pneumatic & Electro- Hydraulic.

SALIENT FEATURES :

- Cast & Fabricated constructions possible.

- Compliance with: IS 13095, AWWA C504, BS 5155, API 609 standards.

- Shaft Seals comprising of elastomeric ‘O’ rings & ‘Lip seals’.

- Concentric, Single, Duo & Tri-eccentric constructions offered for appropriate applications.

- Body is available in flanged end, Wafer end and Lug Wafer design.

- Tri-eccentric constructions are best suits for high temperature applications in hydrocarbon lines and also recommended in water application where there are suspended particles in the fluid.

- Butterfly valve is an ideal substitute for the conventional sluice valve which is used for ON/OFF and regulating duty application.

- 100% leak tightness can be ensured

| Size range | 50mm to 600mm(Wafer—moulded rubber lined body) 200mm to 2500mm (Flanged—Renewable Soft Seal on Disc) |

| Mfg. / Design Std. | IS 13095 /BS 5155/AWWA c504/ /BS EN 593 / API609 |

| Types of valve | Wafer(centric/Concentric)&double flanged(single/doubled Eccentric) |

| Pressure rating | PN 1.0/P.N 1.6/Class –150 |

| Flanged End | IS: 1538 (Tab—4&6), On Request- BS/ANSI/AWWA/DIN/BSEN |

| Body & other C.I. parts | C.I. to IS: 210 Gr.FG-200/260 or BS 1452 or ASTM A126 |

| Body Seat | SS,IS:6603 or AISI-304/316 |

| Seat retanining ring | SS,IS:6603 or AISI 304/316 |

| Shaft | SS.to IS:6603 or AISI 304/316 |

| Disc Seal/Body Lining | Nitrile /EPDM/Viton /BUNA-N |

| Actuation | Lever, Gear with Handwheel, Electric /Pneumatic Actuator |

| Additonal Accesories | External y-pass, Extn. Shafting & headstock arrgt. Locking(to facilitate removal of gear box.) |

| Special Features | • Available In Wafer Single Flange /Wafer Lugged design • The integral liner concept in fall safe design • Suitable for bi-directional Installation to zero leakage • Less wear and tear of seal and longer life Self-cleaning and non-jamming seat design • On request metal sealing design(Up to 600mm dia) • Available in S.G. Iron ,Cast steel & Stainless Steel |