Air Cushion Valve

The principle of this Air Cushion Valves is to allow large quantities of air in the pumping main during separation, entrap the air, compressed it with the returning air column and expel the air under controlled pressure so as to dissipate the energy of the returning water column. The valve has a spring loaded air inlet port, an outlet normally closed by float, a spring loaded outlet poppet valve and an adjustable middle valve control orifice.

When there is sudden stoppage of pump due to power failure, partial vacuum is created in the main. With deferential pressure, the spring-loaded port opens and admits outside air into the main. At atmospheric pressure the inlet valve closes under spring pressure. The entrapped air is compressed by returning water column till the poppet valve opens with float is dropped position, the air is expelled through poppet valve and controlled orifice under predetermined pressure thus dissipating the energy of the returning water column.

SALIENT FEATURES :

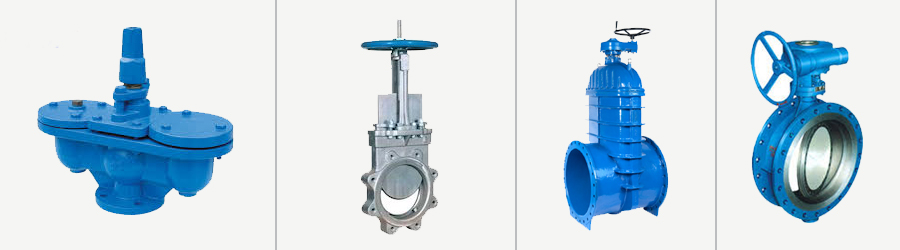

- Available in PN10 / 16 Pressure Ratings.

- Complies with the requirements of MSS-SP-81.

- One-piece trim provides corrosion-resistant, wear-resistant, high-performance shut off over a long service life

- Size Range: 50 mm to 1500mm

- Both Bi-directional and Uni-directional sealing arrangements are available

- The types of operators offered are Manual Hand wheel, Gear Box, Electrical & Pneumatic.

| Size range | 50mm to 300mm |

| Mfg. / Design Std. | AWWA M 51 |

| Types of valve | Specially designed non-slam, surge dampening and suppressing |

| Pressure rating | PN 1.0 / PN1.6 / PN 2.0 / PN 2.5 |

| Flanged End | IS: 1538 (Tab – 4&6) on request – BS/ANSI/AWWA/DIN/BSEN |

| Body & Other M.S | M.S. to IS: 2062 Gr. Fe-410-W |

| Parts | |

| seat | Brass |

| Ball Float | Wood (Rubber Coated ) / S.S. |

| Air Inlet Valve | Mfr’s Std |

| Air Outlet Valve (Adjustable) | Mfr’s Std |

| Cushioning | Operate to break the vacuum where separation takes place and Reduce the inertia of returning water column by using air intake |

| Functioning | • Discharge large quantities of air form pipeline during pipe filling. • Admits large quantities of air during pipe drainage or at water column separation. • Air Valve closes when the pipe fills up with liquid, and does not reopen until pressure within air valve (pipeline) drops below the atmospheric pressure. |

| Special Features | • Alternatively called Quick release Damped Air Valve (QRDA). • Maximum flow efficiency and surge protection. • To protect from water hammer damages • To protect from vacuum enhanced problems and damages. • Available in cast iron & Ductile Iron. |